WATCH CEO Alex Hanly discuss The Lithium Gap in the conversion capacity and Lithium Universe’s (ASX: LU7) mission of enhancing the North American supply chain.

Lithium Universe Limited has appointed Primero Group Limited (Primero) as lead manager in relation to the design of a multi-purpose stand-alone concentrator (Concentrator Engineering Study). This appointment is consistent with the business model and will form part of the Company Québec Lithium Processing Hub (QLPH) strategy.

Founded in 2011, Primero specialises in providing design, construction, and operational services for resource projects worldwide. With extensive experience in the lithium sector, Primero’s vertically integrated business model provides for Build, Own, and Operate (BOO) capabilities, enabling its clients to conserve their capital expenditures whilst expediting the transition from an exploration-based, to production-based business operation.

The appointment of Primero to undertake the Concentrator Engineering Study follows an extensive process to procure a contractor with the suitable experience and capabilities to undertake the design of a stand-alone concentrator with the ability to process 1 Mtpa of spodumene ore. The expected design is anticipated to be similar to that of the Mt Cattlin plant, which uses a simple dense media separation (DMS).

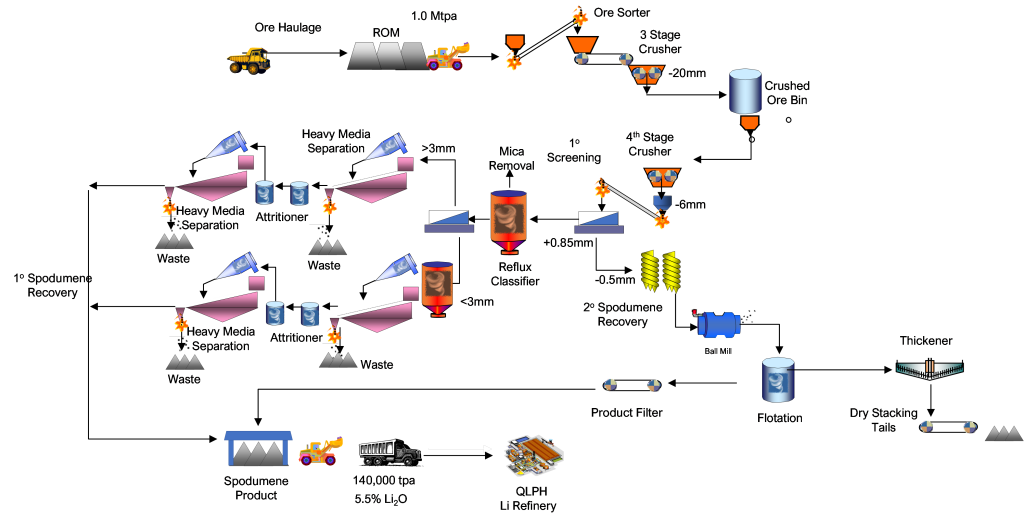

The finalized design flow sheet outlines a four-stage crushing process to generate crushed ore ranging from 0.85mm to 6mm in size. Any crusher fines smaller than 0.85mm identified by the screens will undergo processing in a dedicated flotation unit. The spodumene recovered from this process will undergo drying and then be blended with the final spodumene concentrate. Additionally, any mica present in the crushed ore will undergo removal using a reflux classifier. Subsequently, the material will be split into two streams: one less than 3mm and the other greater than 3mm. Both streams will be directed through two-stage dense media separation units. The less than 3mm stream will undergo mica removal via a reflux classifier at the initial stage. The recovered spodumene from both streams will be combined through blending and stored in a dedicated storage shed. To ensure functionality in the Québec climate, the entire plant will be winterized. See Figure 1 for final flow sheet.

Figure 1. QLPH Concentrator Flow Sheet

The Concentrator Engineering Study will also define the process and non-process infrastructure requirements for the concentrator project as well as the definitive estimated capital and operating costs.

The study will address specific project development, delivery, and operating considerations including permitting and approvals, beneficiation flowsheet, risk management, sustainability measures, and product logistics.